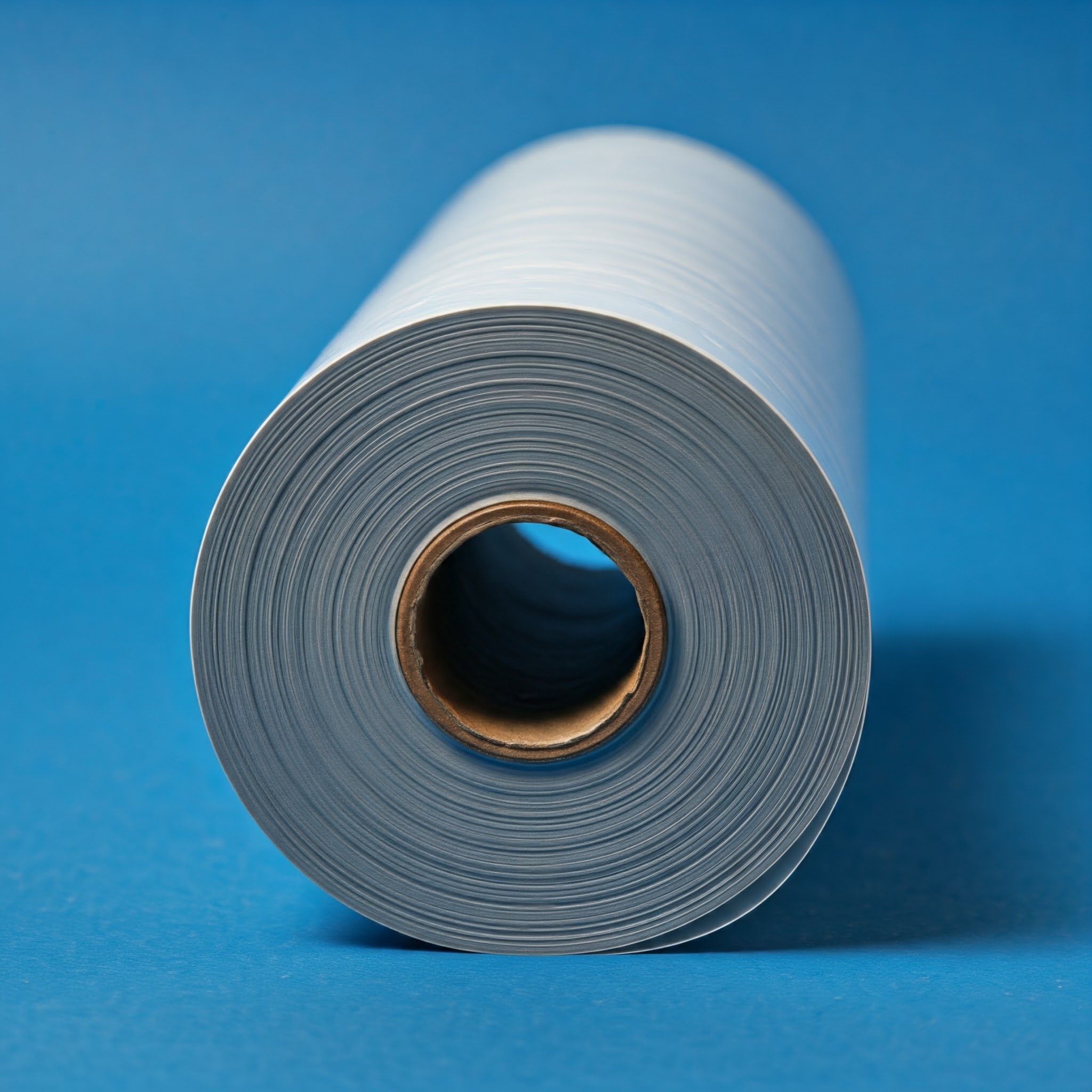

Lamination Film

Food Packaging:

Anti-Fog Properties:

Moisture Resistance:

Enhanced Product Visibility:

Prevents Electrostatic Discharge (ESD):

Protects Sensitive Components:

Maintains Cleanliness:

© Copyrights 2024 Vertx Packaging. . All Rights Reserved.

Design & Develope By WEB PARTNER